Energy & Manufacturing in Appalachia (EMA)

This initiative provides technical assistance and business support to small and medium manufacturers and enterprises seeking to expand business, production and jobs in the energy supply chains.

Get ConnectedEnergy DIY Tools

Self-Assessment

In 15 minutes, get a report on where you should focus your energy strategies.

Get StartedEnergy Efficient Factory Toolkit

Determine your baseline emissions and create a plan to achieve reduction goals.

Learn MoreIncentive Finder

There are millions of dollars in available grants and tax incentives. Identify which ones are the best fit with the largest ROI.

Get StartedGHG Emissions Calculator

Compute the Greenhouse Gas Emissions through your facilities and operations.

Learn MoreHelping Manufacturers Embrace Energy

Manufacturing companies also need to walk-the-talk on the net zero pathway as they expand manufacturing in these industries, and reinvest money from saved energy in business and workers. EMA helps with these initiatives through emissions reductions assessments and implementation strategies that increase efficiency and reduce production costs.

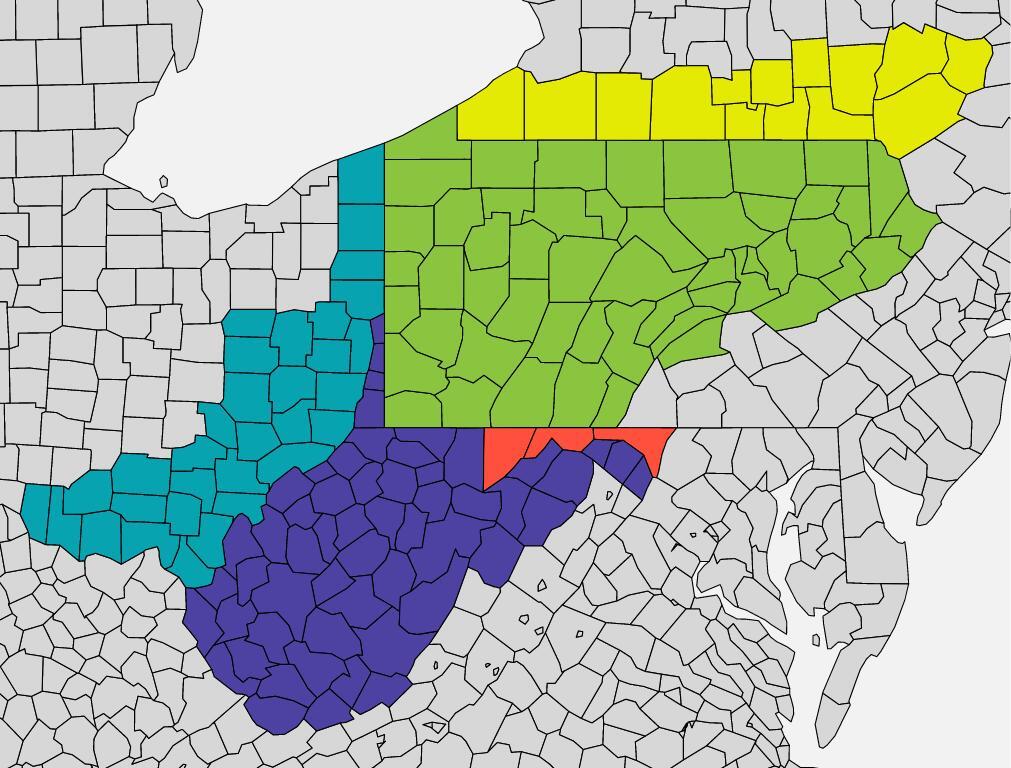

The Appalachian region of 156 counties of Maryland, New York, Ohio, Pennsylvania, and West Virginia has been central in the coal energy sector which powered American manufacturing might, and to the natural gas industry which is now a cornerstone of America’s energy independence. EMA was established to help small and medium manufacturers be a part of this Energy Economy. This program is managed by Manufacturing Extension Partnership (MEP) organizations from five Appalachian states. The activities and intended outcomes of EMA align with the National Institute of Standards and Technology (NIST) MEP and its mission to enhance the productivity and technological performance of U.S. manufacturing.

Get ConnectedThis energy economy vision builds on the competitive assets of the region and looks to create an Appalachian Decarbonization Hub with key elements that will include:

Power Generation & Management

- Electric Grids

- Geothermal

- Hydropower

- Hydrogen Production

- Natural Gas

- Nuclear

- Solar

- Wind

Product-Related

- Batteries

- Chemicals

- Circular Plastics

- Energy Efficiency

- Grid Components

- Low-Carbon Products

Connections

Manufacturers should connect with their local MEP Point of Contact to learn more about EMA opportunities:

- PENNSYLVANIA

Catalyst Connection (southwestern part of PA MEP)

Tom Reed

treed@catalystconnection.org

(412) 918-4269 - Johnstown Area Regional Industries (JARI)

Dave Grimaldi

dgrimaldi@jari.com

(814) 262-8366 - IMC (central part of PA MEP)

Dennis Gilbert

dennisg@imcpa.com

(570) 329-3200 - MANTEC (south central part of PA MEP)

Bruce Newell

bruce@mantec.org

(717) 833-6196 - MRC (central east part of PA MEP)

Shawn Furman

Shawn.Furman@mrcpa.org

(610) 737-2529 - NEPIRC (northeastern part of PA MEP)

Drew Mackie

drew@nepirc.com

(570) 704-0035 - NWIRC (northwestern part of PA MEP)

Robert Zaruta

rzaruta@nwirc.org

(814) 217-6061 - OHIO

MAGNET(part of Ohio MEP)

Janelle M. Lee

jlee@manufacturingsuccess.org

(513) 257-5338 - WEST VIRGINIA

WVU (and WV MEP)

David Carrick

david.carrick@mail.wvu.edu

(412) 327-9119 - MARYLAND

Maryland MEP

Michael Kelleher

mkelleher@mdmep.org

(443) 343-0085 - NEW YORK

AMT (part of New York MEP)

Carol Miller

cmiller@amt-mep.org

(607) 774-0022 x316

Funding for this initiative was provided through the following grants from the Appalachian Regional Commission (ARC):

- Manufacturing the New Energy Economy in Appalachia – ARISE Grant

- Tri-State Net Zero – POWER Grant

- ShalePOWER 2.0: Supporting Appalachian Businesses to Diversify into the Shale-Manufacturing Sectors

This initiative is targeted to the following 156 counties across five states in Appalachia:

-

- Maryland – Allegheny, Garrett, and Washington

-

- New York – Allegany, Broome, Cattaraugus, Chautauqua, Chemung, Chenango, Cortland, Delaware, Otsego, Schoharie, Schuyler, Steuben, Tioga, and Tompkins

-

- Pennsylvania – Allegheny, Armstrong, Beaver, Bedford, Blair, Bradford, Butler, Cambria, Cameron, Carbon, Centre, Clarion, Clearfield, Clinton, Columbia, Crawford, Elk, Erie, Fayette, Forest, Fulton, Greene, Huntingdon, Indiana, Jefferson, Juniata, Lackawanna, Lawrence, Luzerne, Lycoming, McKean, Mercer, Mifflin, Monroe, Montour, Northumberland, Perry, Pike, Potter, Schuylkill, Snyder, Somerset, Sullivan, Susquehanna, Tioga, Union, Venango, Warren, Washington, Wayne, Westmoreland, Wyoming

-

- Ohio – Adams, Ashtabula, Athens, Belmont, Brown, Carroll, Clermont, Columbiana, Coshocton, Gallia, Guernsey, Harrison, Highland, Hocking, Holmes, Jackson, Jefferson, Lawrence, Mahoning, Meigs, Monroe, Morgan, Muskingum, Noble, Perry, Pike, Ross, Scioto, Trumbull, Tuscarawas, Vinton, Washingtons

- West Virginia

- – Barbour, Berkeley, Boone, Braxton, Brooke, Cabell, Calhoun, Clay, Doddridge, Fayette, Gilmer, Grant, Greenbrier, Hampshire, Hancock, Hardy, Harrison, Jackson, Jefferson, Kanawha, Lewis, Lincoln, Logan, Marion, Marshall, Mason, McDowell, Mercer, Mineral, Mingo, Monongalia, Monroe, Morgan, Nicholas, Ohio, Pendleton, Pleasants, Pocahontas, Preston, Putnam, Raleigh, Randolph, Ritchie, Roane, Summers, Taylor, Tucker, Tyler, Upshur, Wayne, Webster, Wetzel, Wirt, Wood, Wyoming

Resources

Assessments are available to allow manufacturers to identify the best strategies to achieve their unique goals. Start with this self-assessment to get an idea of the awareness and opportunities in energy. This can lead to a site assessment or other engagement tailored to company needs.

Self-Assessment – Energy Manufacturing Economy

Assess one of manufacturing’s largest expenses – electricity. Enter the electric bill information and receive information about ways to lower costs and apply for funding for efficiency projects. Click this link to open the Bill Analyzer tools.

There are several assessments and tools available to help a company obtain information and analysis about their current energy usage. Here are some programs to look at:

Energy Supply Chain Products and Markets offers numerous resources to help companies learn about the energy industry and identify strategies and opportunities to work in the supply chain. Engagement professionals are available to share information about the regional players in energy segments. They can also offer a one-on-one look at how a company might be most successfully involved in the energy supply chain, including recommendations for next steps on that journey.

Energy efficiency strategies help manufacturing companies to proceed with efficient energy practices and practical cost reduction strategies. The first step is to identify the team of employees to support cost-reduction strategies. Second, establish a baseline understanding of current energy usage. Third is to identify opportunities to make changes. Fourth is to look at the driving forces for making a change – such as 1) save money with energy efficiency, 2) satisfy requirements by current or potential customers, 3) comply with regulatory standards, 4) be a good community partner. This will lead to establishing goals and actions for improvement and a way to measure progress. The EMA program developed the The Energy Efficient Factory Toolkit to walk companies through this process. Download it to start your journey or to enhance your current strategies.

Download The Energy Efficient Factory Toolkit

In addition to the The Energy Efficient Factory Toolkit, these resources can provide insight and resources for manufacturing companies:

Startup Mini-Grant Program

Do you have a new business that makes products in an energy supply chain? The Energy & Manufacturing Startup Assistance Program is here to help jumpstart your journey with up to $2,500 in funding! Applications are open now and will be accepted through April 25, 2025.

You are eligible if:

- Your business was formed on or after October 1, 2022, or will launch by August 15, 2025

- You currently manufacture or plan to manufacture a product

- You support or aim to support the energy supply chain

- You’re located in one of 47 counties across Ohio, Pennsylvania, or West Virginia

——————————————————————————————————————————

Subcity Incentive Finder

The EMA program has contracted with Subcity to offer the Incentive Finder service at no cost (a $1,000 value). Eligible manufacturing companies will receive a personalized report from Subcity that identifies the grants and tax incentives that have the biggest ROI and greatest likelihood of success. Subcity can also assist the company to apply for the incentives for an additional fee.

—————————————————————————————————————————–

EMA Mini-Grant Program

EMA offers mini-grants of up to $10,000 to support manufacturers who engage in a technical assistance project that will assist them to: 1) engage with the energy supply chain and/or 2) implement energy cost-reduction strategies. These are reimbursement grants awarded after the project is completed to help offset some of the investment cost by the company.

Energy & Manufacturing Mini-Grant Program Guidelines

—————————————————————————————————————————–

Additional Grant and Incentive Opportunities

There are additional grant and tax incentive opportunities that a company may qualify depending on various factors (location, industry, business size, ownership type, etc.) Here are some programs to look at:

Events

Webinar: Energy Audits: Why Now Is the Best Time

April 25, 2025 | Virtual

This webinar provides emerging leaders with a number of examples of energy audits and helps them understand how to implement energy audits at their organization.

Learning Objectives

- Learn what’s involved with energy audits by exploring industry examples and terminology

- Discover best practices on how to engage your colleagues and your organization as a whole to move forward with an energy audit

Videos: Unlocking Sustainable Solutions

Explore the transformative landscape of Clean Energy Manufacturing through our on-demand video series, delving into expert insights and practical knowledge to empower sustainable practices in your operations.

Get Connected

Connecting with Energy & Manufacturing

The Energy & Manufacturing in Appalachia initiative supports small and medium-sized manufacturers (SMMs) in eligible counties to expand business, production, and jobs in energy supply chains and reduce costs through factory efficiencies.